Why it’s important to pre-lube your new turbocharger?

One of the most important yet often overlooked stages of installing a new turbocharger is Pre-Lubing. Omitting this step can lead to premature wear and tear, or, in the most extreme cases, turbo failure upon start-up.

Oil is your turbo’s best friend

Turbochargers are highly complex machines, subject to remarkably high rotational speeds and operating to incredibly precise clearances. It takes just a few seconds for a lack of oil to cause catastrophic damage.

The thin, golden lining

The tolerances of these high-precision parts are marginal, and the revolution speeds can exceed 100,000 revolutions per minute. The central axis, movable vanes, and the turbine wheel are centred using a thin film of compressed engine oil.

That thin film is the only thing protecting the moving components of a turbocharger from friction.

While the turbo is in storage for extended periods of time, the oil succumbs to gravity, often leaving the oil passages dry.

Now imagine starting a turbo without that crucial thin lubricating film in place. Most turbos will start spinning at extremely high RPM very quickly, and before the engine oil makes its way to the bearings, the shaft, and other friction points, the damage has been done.

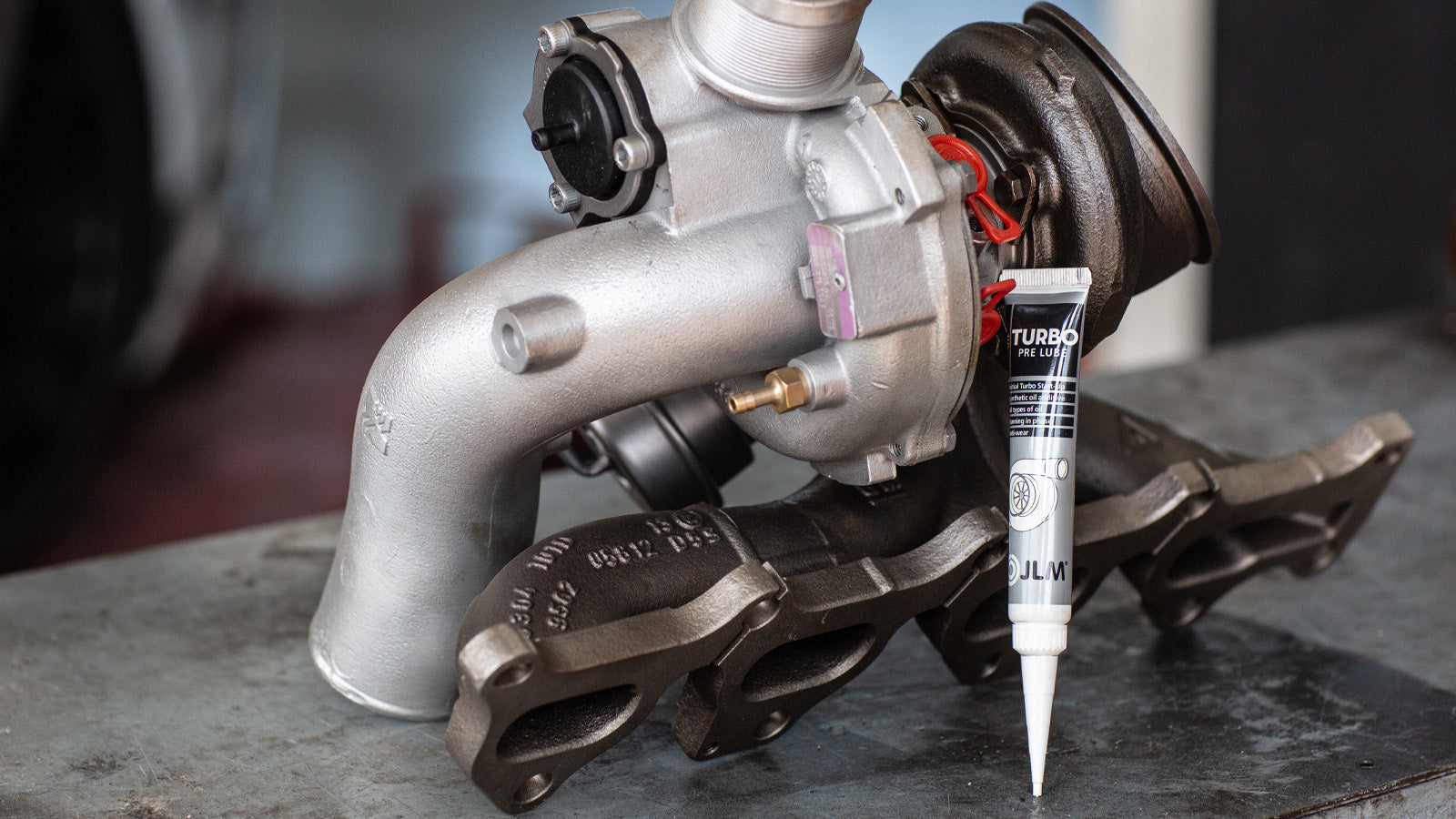

Pre-Lubing is a short and easy process that ensures your turbo’s longevity, performance and optimal efficiency. Using a good quality, fully synthetic pre-lube like the JLM Turbo Pre-Lube is highly recommended.

The location of the Oil Feed (inlet) port varies from turbo to turbo but usually, the inlet will be the smaller, threaded port at the top of the turbo, while the Oil Drain (outlet) port will be the larger, usually unthreaded port at the bottom of the turbo.

Pre-Lubing your turbo before start-up

- Dispense the tube of Pre-Lube to the turbo OIL INLET hole

2. Manually turn the compressor wheel to distribute the Pre-Lube around the bearings.

3. Pre-fill and fit the oil feed line.

4. Fit the inlet and outlet air hoses to the compressor housing, making sure the connection is air-tight.

5. Without starting the engine (disconnect fuel or ignition), crank the engine for 10-15 seconds to prime the oil feed to the turbo.

6. Reconnect fuel / ignition and start the engine.

7. Run the engine at idle for 3-4 minutes to check for any oil, gas or air leakage.

Remember, turbochargers are high-tech, complex and precision-built mechanical devices that rely on lubrication to function. Ensuring adequate lubrication right from the start will prevent expensive repairs or premature wear and tear.